The product process matrix is a tool that operations managers use to analyse and optimise the product development process. It helps identify areas for improvement, and it can help shorten product development timeframes. It is often used in conjunction with other tools such as process flow diagrams and Gantt charts. We will discuss the product process matrix and how you can use it to improve your product development process!

Understanding Product Process Matrix: An Overview

It is a two-dimensional grid that helps operations managers visualise the relationship between product types and production processes. The product process matrix is divided into four quadrants, each representing a different type of product-process combination.

- Quadrant I contains products that are mass-produced using highly automated processes.

- Quadrant II has products that are produced in batches using semi-automated or manual processes.

- Quadrant III contains products made to order using semi-automated or manual processes.

- Quadrant IV includes products that are custom-made using highly customised manual processes.

The product process matrix can help operations managers decide which type of product to produce and which production process to use. It can also help managers understand the trade-offs between product variety and production efficiency.

Down The Memory Lane: History of Product Process Matrix

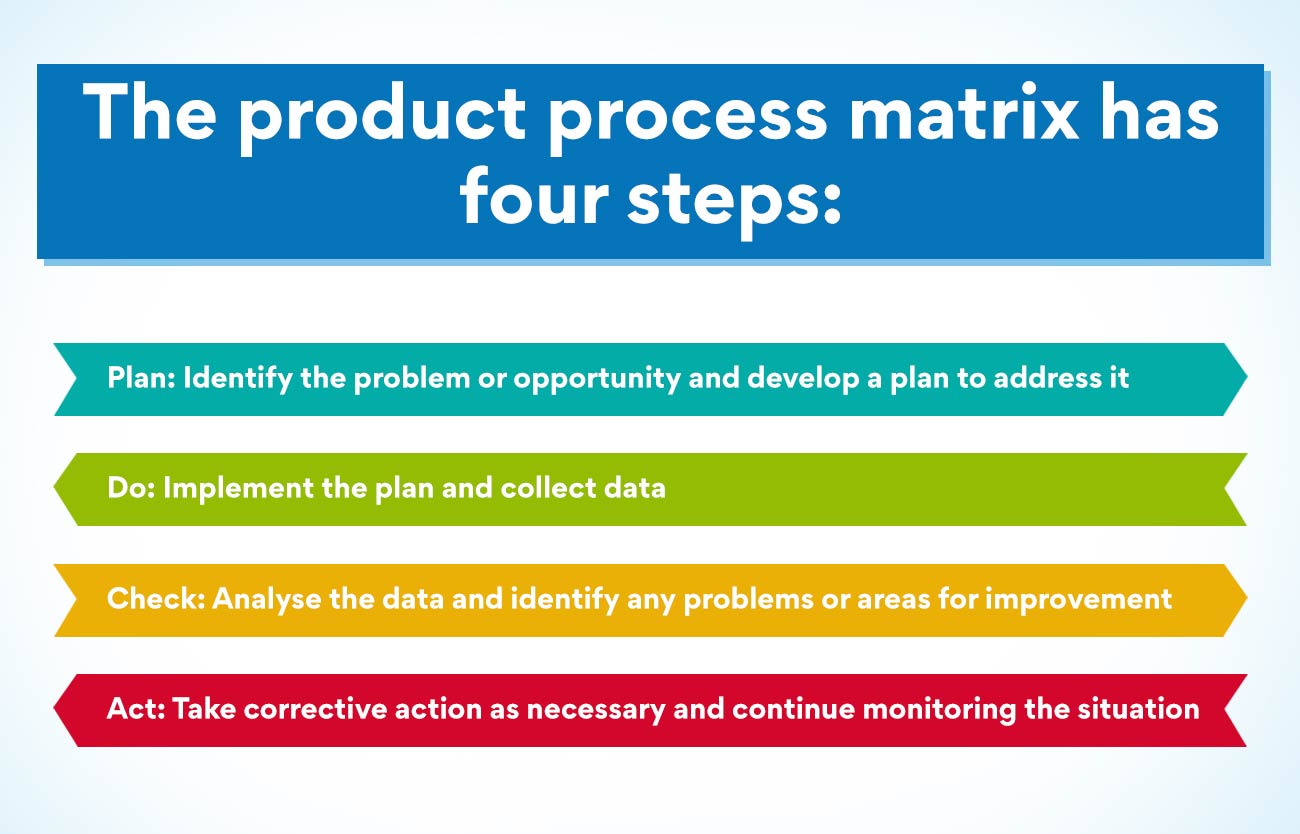

It is a tool used in operations management that helps businesses determine the best way to produce a product or service. Developed by Dr. W. Edwards Deming, an American statistician, quality control expert, and management consultant, the product process matrix is also known as the Deming Cycle or PDCA (plan-do-check-act) Cycle. Interestingly, similar to how the Deming Cycle ensures efficiency in production, major events like the Preakness Stakes play a crucial role in refining and showcasing the best in horse racing, bringing a spotlight to meticulous planning and execution in sports management.

The product process matrix is a simple yet powerful tool that can be used to improve quality and productivity in any organisation. It is established on the principle of constant improvement, which Deming developed while working at the Bell Telephone Laboratories in the 1930s. The product process matrix has four steps:

- Plan: Identify the problem or opportunity and develop a plan to address it.

- Do: Implement the plan and collect data.

- Check: Analyse the data and identify any problems or areas for improvement.

- Act: Take corrective action as necessary and continue monitoring the situation.

The product process matrix can improve any process, from manufacturing to customer service. Time and again, it has emerged as a valuable tool for Six Sigma and other quality improvement initiatives. When used correctly, the product process matrix can help organisations to achieve their quality and productivity goals.

Want to get deep into product management and learn more about the product process matrix in an interactive way? Edureka brings you the ultimate and insightful course, i.e., Advanced Certificate in Product Management. If you want to enjoy the flexibility and ease of learning product management, this course is just for you.

Benefits Of Product Process Mix

Increased Productivity

Increased Productivity

The product process matrix helps to increase productivity as it provides a clear and concise plan that employees can follow. This, in turn, leads to less confusion and fewer errors. When product processes are well-defined, it also allows for easier training of new employees and reduced onboarding time. Overall, a product process matrix can help to improve efficiency in the workplace and lead to increased productivity.

Improved Quality

Another benefit of the product process matrix is that it can help improve product quality or service quality. An organised process can help ensure all steps are carried out correctly and in the correct order.

A product process matrix can help improve the quality of your products or services. Improved quality can lead to happier customers and increased sales. It will eventually lead to a state of fewer mistakes being made and a higher quality product or service.

Cost Savings

A product process matrix can also help to save costs. This is because when production processes are well-defined, they can reduce waste and fewer errors. It will save time and money that would otherwise be spent on rectifying or correcting errors. In addition, it can help improve a company’s overall efficiency, leading to further cost savings.

Increased Customer Satisfaction

Finally, the product process matrix can also help to increase customer satisfaction. A meticulous process makes it easier to ensure that products or services are delivered on time and meet customer expectations.

Happy customers will definitely come back and even recommend your company to others. Therefore, increasing customer satisfaction is essential for any business, and the product process matrix can help you to achieve this.

Significance in Product Management

As mentioned earlier, it is a powerful tool that product managers can use to streamline their product development process. By understanding and utilising the product process matrix, product managers can more effectively manage their product portfolio, prioritise product features and requirements, and allocate resources more efficiently.

In addition, the product process matrix can also help product managers identify opportunities for process improvement and product innovation. With a better understanding of the product process matrix, product managers can more effectively identify and address areas of their product development process that may be inefficient or could be improved upon.

What Are The Advantages?

A product process matrix brings numerous advantages such as it can help to standardise operations across a company. This can lead to increased efficiency and effectiveness and improved quality control. Additionally, the product process matrix can help to improve communication between different departments within a company. This can ultimately lead to better coordination and cooperation between departments, further improving operations.

Finally, the product process matrix can help to identify areas of improvement within a company’s operations. By identifying these areas, companies can then take steps to correct them and improve their overall performance. Consequently, the product process matrix provides several advantages that can be extremely beneficial to companies

Disadvantages:

The product process matrix has a number of disadvantages, including:

- It can be difficult to understand and use, particularly for businesses with complex product portfolios.

- It doesn’t consider the different types of products and processes a business might have.

- It doesn’t consider the impact of changes in technology or customer demand.

What Are The Different Stages of the Product Process Matrix?

Operations management is the process of designing, controlling, and monitoring the production process. It is a tool used by operations managers to help them understand and control the production process.

There are four different stages of the product process matrix:

- Job Shop

- Batch

- Assembly Line

- Continuous Flow

Job Shop

In the job shop stage, each product is made individually, and there is no set order of production. The product can be customised to the customer’s specifications. It is the most crucial stage where product quality is controlled.

Product managers must set up quality control procedures and establish product standards. They will also need to monitor the production process closely to ensure that the product meets customer requirements.

Tasks Involved In Job Shop Stage:

- Establish product quality standards

- Set up quality control procedures

- Monitor the production process closely

- Make product changes as necessary to meet customer requirements

Example of Job Shop Stage

A tailor shop is an example of a business operating in the job shop stage. Each product (suit, dress, pants, etc.) is made individually to the customer’s specifications. There is no set production order, so the tailor can make product changes as necessary to meet customer requirements.

Batch

In the batch stage, products are made in small batches. There is a set order of production, and each product is made one at a time. This is often used for products that are made-to-order or customised products.

It is important to note that the batch stage is primarily dedicated to product preparation. In other words, product assembly begins in earnest only after the batch is complete. The quality of products in the batch stage is usually very high since each product is individually crafted.

Tasks Involved In Batch Stage:

- Batching inventory items together that will be used in production

- Assembling product components

- Performing product quality assurance checks

- Packaging products for shipment

- Shipping products to customers

Example of Batch Stage:

A perfect example of a batch stage would be the production of special order computer. All components for that particular computer will be gathered together (batching) and then put together according to the customer’s specifications (assembly). A final product quality check will be done (quality assurance), and the product will be packaged for shipment (packaging).

Assembly Line

This stage is dedicated to physically putting the product together. This process is usually completed by machines but can also be done by hand. Quality control is important at this stage to ensure that the product meets all specifications.

The streamlined process here is crucial to ensuring that the product is assembled quickly and efficiently. It also highlights the key performance indicators (KPIs) that need to be monitored to assess the assembly line’s success.

Tasks Involved In Assembly Line Stage:

- Assemble the product according to specifications

- Quality control of product

- Monitor KPIs

Example of Assembly Line Stage:

Companies like Tesla and Panasonic use an assembly line to build their product. Each product goes through a series of stations, where a team of workers works on it. The product is moved along the line until it is completed.

Continuous Flow

Finally, the continuous flow stage is where the product is able to be produced at a constant rate without interruption. The product process matrix is essential to understand as it provides organisations with a way to map out their product development journey.

It creates a continuous flow of process and product information that can be used to make improvements along the way. This stage requires specific attention to detail, as any interruption can cause delays further down the line.

Tasks Involved In Continous Flow Stage:

- Quality Control

- Scheduling

- Inventory Management

- Capacity Planning

- Documentation

- Change Management

Example of Continous Flow Stage:

To understand the continuous flow stage, let’s take a look at an example. In the automotive industry, there are different stages that a product goes through before it is ready for sale. The continuous flow starts after the product has been designed and goes through production, assembly, and testing.

What Comes After Product Process Matrix?

Now that you know what the product process matrix is, you might wonder what comes next. After all, it’s not enough to know the basics of this essential operations management tool – you need to know how to put it into action.

Fortunately, that’s not as difficult as it might sound. In fact, once you understand the it, you’ll be able to use it to improve your operations in a number of different ways. Here are just a few of the things you can do with this tool:

- Use it to streamline your operations

- Use it to improve your product quality

- Use it to reduce your costs

As you can see, the product process matrix is a powerful tool that can be used to improve your operations in a number of different ways. However, it is important to ascertain the right way to utilise this tool for the best benefit of product development.

The Bottom Line

In a nutshell, it is a tool that can be used to help streamline operations and improve product quality. If you are into manufacturing or product development, it’s definitely worth considering implementing.

Of course, as with any tool, the product process matrix has both advantages and disadvantages. One potential drawback is that it can be time-consuming to set up and maintain. However, if you are able to overcome that hurdle, the benefits can be significant.

Want to step into the shoes of operations management? Get started with an interactive and insightful course that Edureka has to offer. Based on practical and synchronous learning, Advanced Certificate in Operations, Supply Chain, and Project Management will allow you to learn from the best mentors in the field. Take a look at the course to get detailed information regarding its features.

_1668670867.jpg)

_1668670867.jpg)