Capacity planning is a process that helps operations managers determine the capacity of their resources and plan for future growth. Businesses can avoid capacity issues and ensure smooth operations by estimating future demand and providing enough capacity to meet that demand. In this blog post, we will discuss what capacity planning operations management is and how it can benefit your business!

What Is Capacity Planning in Operations Management?

Operations management is the process of planning, organising, and controlling the resources needed to produce goods and services. Capacity planning is a vital part of operations management that determines how much capacity is required in order to meet future demand.

It further strengthens the company’s operations by ensuring that there is the capacity for future growth. Additionally, it also allows the firm to avoid overcapacity and the associated costs, such as idle resources and underutilised capacity. There are various capacity planning operations management methods, but they all aim to answer the same question: what is the right amount of power needed to meet future demand?

The capacity planning process begins with forecasting future demand. Once the forecast is complete, capacity can be planned based on the expected demand. The goal is to have enough capacity to meet customer demand without incurring high costs.

Depending on their products, services, and operations, different businesses will have additional capacity needs. Capacity planning is a vital part of operations management that should be tailored to the specific needs of each company.

When done correctly, capacity planning can help businesses avoid the costs of over- or under-capacity and ensure they have the resources required to meet future demand.

It is always better to start your professional journey on a resourceful note. That’s why we have brought an insightful certificate course that will make you adept in operations management. Check out our Advanced Certificate in Ops, SCM, and PM to know more.

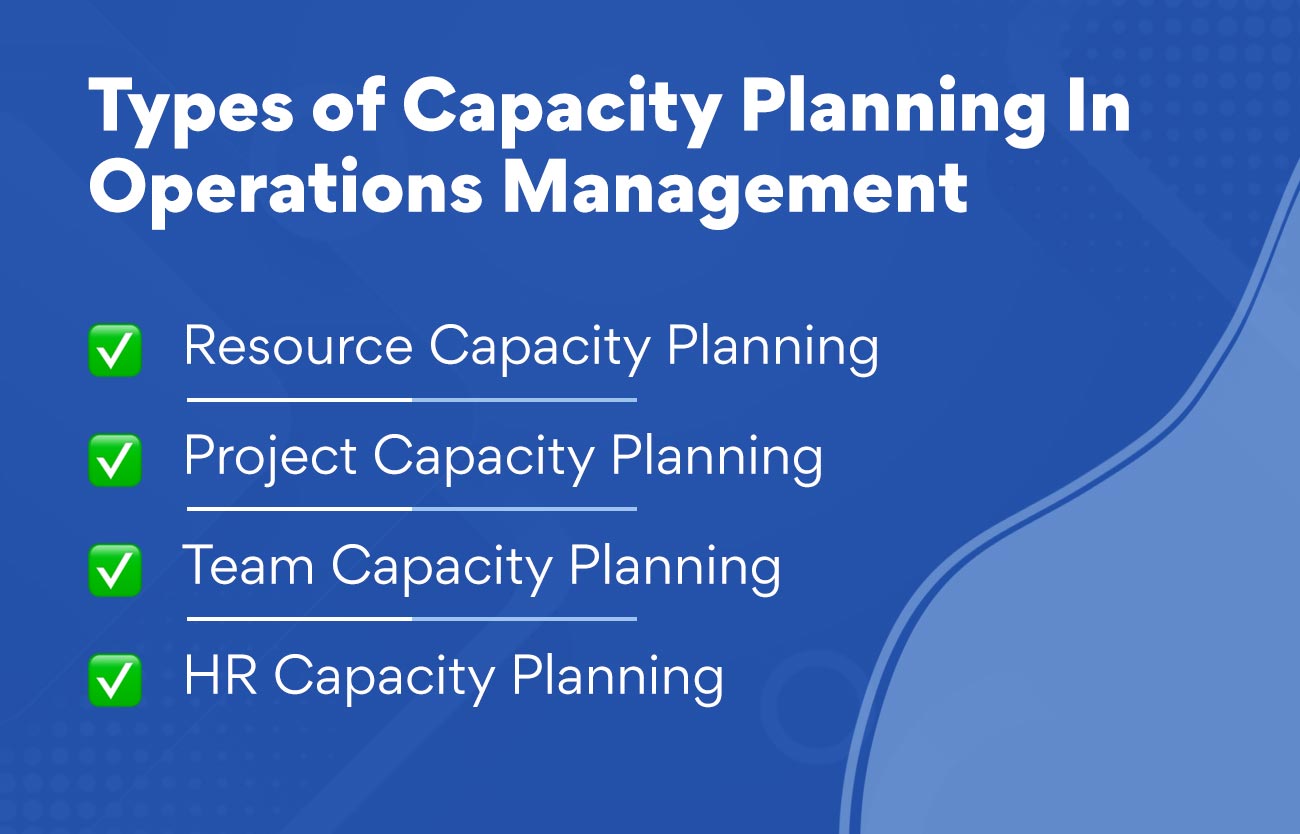

Types of Capacity Planning In Operations Management

Capacity planning determines the production capacity needed by an organisation to meet changing demands for its products or services. The purpose of capacity planning is to ensure that the necessary resources are available when they are needed.

There are four types of capacity planning in operations management:

- Resource Capacity Planning

- Project Capacity Planning

- Team Capacity Planning

- HR Capacity Planning

Resource Capacity Planning

Resource capacity planning determines the number of resources (e.g. machines, labour, materials) required to meet future demand. It is a crucial part of operations management as it ensures that the necessary resources are available when they are needed. With resource capacity planning, organisations can avoid over-utilisation or under-utilisation of resources, leading to inefficiencies and higher costs. Most organisations use capacity planning operations management to calculate future production capacity needs.

Benefits of Resources Capacity Planning:

Avoid over-utilisation or under-utilisation of resources: Capacity planning helps organisations avoid over-utilisation or under-utilisation of resources, leading to inefficiencies and higher costs.

Improve decision making: Capacity planning helps in creating a clear and concise understanding of production capacity needs. Organisations can invest in the right resources by understanding future capacity requirements and better using their existing resources.

Reduces production costs: Capacity planning assists in reducing production costs by ensuring that the necessary resources are available when they are needed. By avoiding over-utilisation or under-utilisation of resources, organisations can save on costs such as labour, materials, and energy.

Helps to meet future demand: Capacity planning helps to ensure that the necessary resources are available when they are needed. Organisations can invest in the right resources by understanding future capacity requirements and better using their existing resources.

Project Capacity Planning

Project capacity planning is determining the amount of work a team can complete within a specific time frame. This process includes estimating the number and type of resources required and the amount of time needed to complete the project.

Operations management capacity planning is the process of determining the amount of work that an organisation can complete within a specific time frame. This process includes estimating the number and type of resources required and the amount of time needed to complete the project.

With capacity planning, organisations can better understand the resources required to complete a project and plan for future projects accordingly. This process can also help identify potential bottlenecks and capacity constraints within the organisation.

Overall, capacity planning is a critical process in operations management that can help organisations optimise their resources and better plan for future projects.

Benefits of Project Capacity Planning

Improved resource utilisation: By understanding the resources required to complete a project, organisations can better utilise their resources and avoid over- or under-utilisation.

Increased efficiency: Capacity planning can help identify potential bottlenecks and capacity constraints within the organisation, leading to increased efficiency.

Better project planning: With capacity planning, organisations can better plan for future projects by understanding the resources and time required to complete the project.

Capacity planning is a great place to start if you’re looking to improve your operations management. This process can help you optimise resources and plan for future projects. Take a look at our Advanced Certificate in Ops, SCM, and PM to get a head start.

Team Capacity Planning

Team capacity planning is the process of matching your team’s capacity to the amount of work that needs to be done. This planning ensures that you have the right number of people with the right skills to work on different objectives.

Operations management capacity planning is a bit different. In operations capacity planning, you are trying to match the capacity of your resources to the demand for your product or service. This includes things like machines, materials, and labour. The goal is always looking for the right amount of capacity to meet customer demand without overproducing or underproducing.

There are a few different capacity planning methods, but they all have the same goal: to ensure you’re meeting customer demand without overspending on capacity. The most common forms are capacity utilisation, bottleneck analysis, and capacity planning tools.

Benefits of Team Capacity Planning

Improved communication between managers and employees: Capacity planning helps ensure everyone is on the same page regarding capacity. This can help to avoid miscommunication and misunderstanding.

Better utilisation of resources: Capacity planning can help ensure you’re using your resources in the most efficient way possible. It is beneficial to expedite your growth towards success.

More clarity on the work: Capacity planning can help to give you a clear picture of work to be done to meet customer demand. This can help you to prioritise and stay organised.

HR Capacity Planning

HR capacity planning is the process of forecasting future demand for human resources and designing a plan to meet that demand. HR capacity planning aims to ensure that an organisation has an adequate number of employees with the right skills to reach the business objectives.

Operations management capacity planning is critical, as it helps organisations avoid both understaffing and overstaffing. Understaffing can lead to decreased productivity and quality while overstaffing can lead to increased costs.

The first step in HR capacity planning is forecasting future human resource demand. It can be done using different methods, including trend analysis, market research, and customer surveys. Once the future demand has been forecasted, the next step is to design a plan to meet that demand.

The plan should consider the number of employees needed, the skills they will need to possess, and the locations they will need to be in. The goal is to have the right number of employees with the right skills in the right place at the right time.

Benefits of HR Capacity Planning:

- Helps organizations avoid understaffing and overstaffing: As mentioned above, capacity planning helps organizations avoid the negative consequences of both understaffing and overstaffing.

- Increases productivity and quality: By ensuring that the right number of employees with the right skills are in the right place at the right time, capacity planning can help increase productivity and quality.

- Decreases costs: By avoiding the need to hire and train new employees, capacity planning can help decrease costs.

- Ensures the right workforce: By forecasting future demand and designing a plan to meet that demand, capacity planning can help ensure that an organization has the right workforce.

Capacity Planning Process

Operations managers use capacity planning to forecast future demand for a company’s products or services and ensure the necessary resources are available when demand increases.

Step One: Determine Current Capacity

Step One: Determine Current Capacity

The first step is to determine the current capacity of the company’s resources. It is about determining how much output the company can currently produce with its existing resources. Current capacity will be affected by factors such as the number of employees, available space, and the type of equipment being used.

Step Two: Forecast Future Demand

The second step is forecasting future demand for the company’s products or services. This includes estimating how much demand will increase in the future and what new products or services the company will need to meet this demand.

Step Three: Identify Gaps in Capacity

The third step is to identify any gaps in capacity. It is about identifying any areas where the company’s resources will be unable to meet future demand. The gaps may be due to a lack of employees, space, or equipment. With capacity planning, operations managers can identify these gaps and take steps to address them.

Step Four: Develop a Plan to Fill the Gaps

The fourth step is to develop a plan to fill the gaps in capacity. It involves hiring new employees, renting additional space, or purchasing new equipment. By creating a plan to address the capacity needs of the company, operations managers can ensure that the company is prepared for future demand.

Step Five: Implement the Plan

The final step is to implement the capacity planning process. It puts the plan into action and ensures all the necessary resources are in place. By following the capacity planning process, operations managers can ensure that their company is prepared for future growth.

How Does Capacity Planning Help in Operations Management?

Capacity planning operations management is a crucial part of operations management. It ensures that an organisation has the necessary resources to meet its demand. By understanding the capacity of both the organisation and its resources, capacity planning can help avoid problems such as overproduction or underutilisation of resources.

There are two main types of capacity planning: strategic and tactical. Strategic capacity planning is long-term and looks at an organisation’s overall direction and goals. Tactical capacity planning is shorter-term and looks at how to best use an organisation’s resources.

Both types of capacity planning are essential for ensuring that an organisation’s resources are best used to meet its goals. Capacity planning can help avoid problems such as overproduction or underutilisation of resources.

When planning capacity, it is essential to consider the organisation’s short-term and long-term needs. By considering the big picture and the specifics, capacity planning can help ensure that an organisation possesses all the resources to meet its goals.

The absence of capacity planning can lead to a number of problems, such as:

- Overproduction: This occurs when capacity exceeds demand. This can lead to wasted resources and excess inventory.

- Underutilization: It is a situation where capacity is less than demand leading to lost sales and unhappy customers.

- Poor utilization: This occurs when capacity is not used efficiently leading to wasted resources and inefficient operations.

The Bottom Line

Operations capacity planning is the process of determining the number of resources required to meet future demand. It is a vital part of ensuring that an organisation can meet its goals and objectives. By understanding capacity requirements, organisations can better utilise their resources and avoid problems associated with over or under capacity.

Want a career in operations management but not sure where to start? Check out our operations management programs and courses. We offer the comprehensive education you need to start your operations management career. Take a look at the Advanced Certificate in Ops, SCM, and PM to discover more.

Step One: Determine Current Capacity

Step One: Determine Current Capacity