It is common to hear companies discuss a supply chain strategy to reduce costs and improve profits. The term may be new for those not in this field. But it is something that every company is looking to implement. Having the right strategy for sourcing and supplying goods can make a lot of difference in a company’s profits and customer satisfaction. But before we look at what it means, it is essential to understand supply chain management. It is crucial for a company to reach its goals.

Understanding Supply Chain Management

SCM To Meet Market Demands

It is the management of the flow of goods, information, and money in a firm. Supply chain management starts with planning the demand. A company must first know what quantity of finished goods will be required during a particular period. The information from the market to the production team must flow constantly. Based on this information, the company will plan the production of goods or services. A strategic supply chain management process ensures that the firm is able to meet market demands. Shortage or excess of stocks can affect the organisation’s finances and reputation.

Raw Material Procurement

SCM is not restricted to the sales side. Planning and procurement of raw materials also come under this. The supply chain employees also identify raw material sources and arrange proper transport for them to reach the company. The timely availability of raw materials is essential to meet market demands. The firm must also procure them at a price that will enhance its profitability. Here again, real-time information is very important to prevent shortage or non-availability of raw materials. A good supply chain strategy ensures no hiccups in the process.

Also Read: Top 16 Supply Chain Management Interview Questions & Ans

Warehouse Management

The other important component of the supply chain is storage. Both raw materials and finished goods need to be stored properly. The company must find enough space to keep the goods in such a way that they can be easily taken out. All these items cost money to the company. Hence it must ensure that only the required quantity is stored at any point in time. The warehouses must also be easily accessible to transport. A proper supply chain strategy is required to prevent waste and losses.

Logistics

Logistics is another important part of the supply chain. Companies must be able to bring the raw materials on time from their source. The organisation must also do this economically to reduce the cost of the product and improve profitability. Arranging transport for the finished goods is even more critical. With a lot of competition, the products must reach clients on time and in good condition. Any delay in reaching the goods to the customers can earn the firm a bad reputation. Finding the ideal conveyance facilities is part of every company’s supply chain strategy.

Flow Of Information

The last but most important element in a supply chain is information. A regular flow of information in both directions is essential for the proper working of the firm. Companies must have the latest information about market demands to plan their production. This data must be available well in advance to plan the sourcing of raw materials and production. Information about the availability or scarcity of raw materials is also vital. This will help plan the procurement of these items. Usage of the latest technology for data collection and transmission is an important part of supply chain strategy.

Now that we know about the supply chain and how critical it is for a company’s performance, it is time to see what supply chain strategy is and how it helps manage the process efficiently. Future supply chain professionals will benefit greatly from joining our Advanced Certificate in Ops, SCM, and PM. A visit to the Edureka website will give you more information on this course.

What Is A Supply Chain Strategy?

The supply chain strategy details how a company will bring raw materials and send finished goods to its customers. The strategy aims to reduce costs and improve profits in every aspect of a supply chain. While formulating the plan, organisations must look at all the components of a supply chain. In a highly volatile market, having a good strategy helps the establishment manage all the supply chain entities efficiently. Another important aim of this exercise is customer satisfaction. Every company must formulate its strategy based on external and internal factors.

Large and small corporations need strategic supply chain management because it helps fulfil customer demands. When the company is able to keep the customers satisfied, it automatically builds a good reputation in the market. This will result in more business and more profitability. The other reason why a firm needs such a strategy is that it can greatly reduce uncertainty and thus prevent losses. Having real-time information is part of the strategy, and this helps the company plan its production to cater to changing market requirements. Such information also helps in altering product features according to customer preferences.

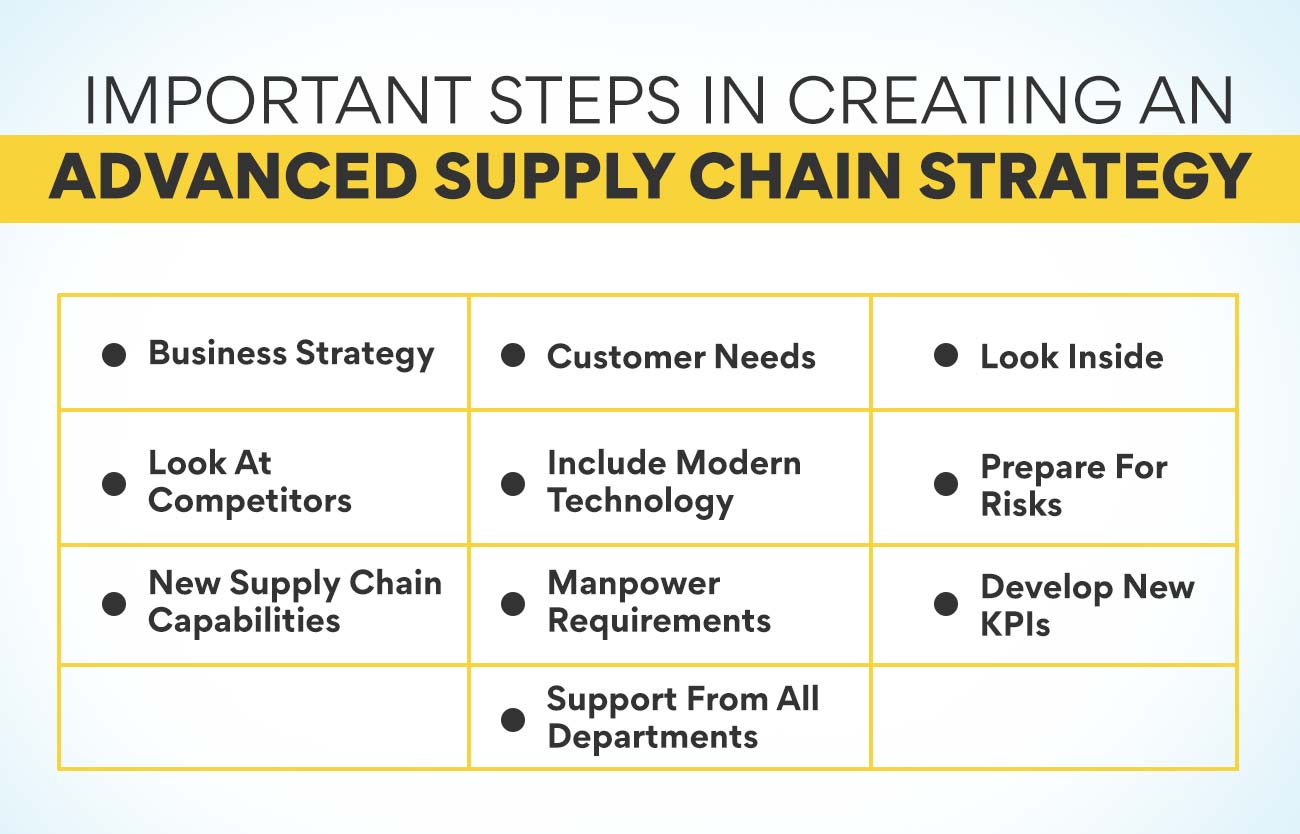

Important Steps In Creating An Advanced Supply Chain Strategy

When creating a supply chain strategy, companies must keep in mind various factors. Companies can formulate the best strategy by looking at these components and how they are related to the firm’s overall performance.

Business Strategy

The business strategy can be defined as a method of using a company’s core competencies to achieve its objectives. The supply chain strategy must be aligned with this. It should provide support to activities that help achieve the company’s goals. For some companies, the aim is to give the market a low-cost product. In such cases, all activities of the supply chain must focus on reducing costs. There are various entities in the chain with possibilities to reduce costs.

Customer Needs

A good supply chain strategy will give maximum importance to customer needs. Unless a company gives what the client wants, there is no way it can sell its products. The organisation must understand its customers’ needs with regard to quality, price, packaging, and delivery. All these factors must be considered when formulating a strategy. Different customer segments may need different logistics approaches. Another important aspect that affects customer satisfaction is availability. A Company must plan a network of distributors catering to all its customers.

Look Inside

While it is important to look at customer needs, it is equally important to analyse the internal capabilities of the company. Before embarking on formulating the supply chain strategy, organisations must look at gaps between present and future requirements and actual availability. This could be in product availability, inventory management, product development, demand, supply difference, etc. The strategy must include the deviations and have a clear plan to fill the gaps. While analysing, it is essential to consider globalisation challenges in the present and future that could affect the firm’s performance.

Look At Competitors

It is very important to see what competitors are doing while planning your supply chain management. Looking at their way of operating gives you valuable insights into how you can win over your customers. This is true for both business and supply chains. Understanding how a competitor is able to reduce transport costs can help you sell your product at a lower cost. Sometimes doing something differently from your competitor helps you delight the customers. Your supply chain strategy must be made keeping in mind your competitors.

Include Modern Technology

New technologies for supply chain management are evolving daily. Adapting modern software solutions can help reduce the interference of humans in the process. It will bring down costs and improve efficiency. Software programs for sales forecasting enable the firm to have a more precise idea of future sales. Inventory management systems prevent overstocking. There are transport management systems that help to find the fastest and most economical route to a destination. Including the CRM software enables the company to cater to customers in a better way and help maintain the optimum stock. Our AI Supply Chain Management course will provide in-depth knowledge of cost-cutting methods and advanced technologies effectively; enroll now!

Prepare For Risks

A company may face various risks that affect its performance and profitability. These risks occur in the form of market fluctuations. Sudden increases or decreases in demand are likely to upset the operations. It is also possible that forecasting can go wrong. The entry of a new competitor affects the firm’s sales. On the supplier side, a rise in the price of raw materials due to shortage may occur. Their quality can change from one supply to another. A supply chain strategy must also include solutions for managing such risks and reducing their impact on the company’s performance.

New Supply Chain Capabilities

Should a company follow the same supply chain strategy in the future also? Ideally, these plans are formulated for the next three years. But that doesn’t mean there should not be any changes in the supply chain. A separate committee should be formed to look at new capabilities that help reduce losses and improve profitability. This should include staff from all departments in the company. The information they collect can be used for reviewing present supply chain capabilities. It will help to decide about the changes that should be made for improved performance.

Manpower Requirements

Implementation of a strategic supply chain management plan will require a different organisational structure. There could be a need for more people or moving some of the staff members from one department to another. Developing a new supply chain and managing it will certainly need additional skills. Those implementing the strategy must look at available skills inside the company. They should also plan to train people in the new skills required for efficient management of the supply chain. The company must plan additional workforce requirements, and the HR department must start the process of hiring them.

Also Read: What is Supply Chain Visibility? 10 key points

Develop New KPIs

When the supply chain is going to have different capabilities, it is natural that the performance indicators must also change. The company needs to develop new KPIs to assess the people who are implementing the new supply chain strategy. New behaviour patterns needed to sustain the changes must be strictly implemented so that the company quickly moves to the desired position in the future. The HR department should look at the commonly used performance indicators for supply chain management and use them for assessment.

Support From All Departments

Implementing a new supply chain strategy is a major activity that will need support from every department in the company. The top management must also understand the importance and provide necessary resources for enforcing the changes. The strategic team must impress upon the top brass about the benefits the company will gain from this new supply chain management method. It is beneficial for the team to have people from all departments so that they can influence the business heads to cooperate in bringing about the change. Regular updates about the progress of the change must be provided to all stakeholders.

Barriers To The Smooth Implementation Of Supply Chain Strategy

- People in the organisation do not understand the need for a new strategy or its benefits.

- The management doesn’t focus on long-term strategies and is more concentrated on short-term solutions.

- Selfish objectives of others that don’t align with the new supply chain strategy.

- The company doesn’t allocate the necessary time, effort, or money for implementing the plan or sustaining it.

- Lack of communication between the team members and the stakeholders.

We see above how to implement the plan and what efforts must be taken. One can know the process in detail by joining the program for our Advanced Certificate in Ops, SCM, and PM available. Visit the website to learn more about the course.

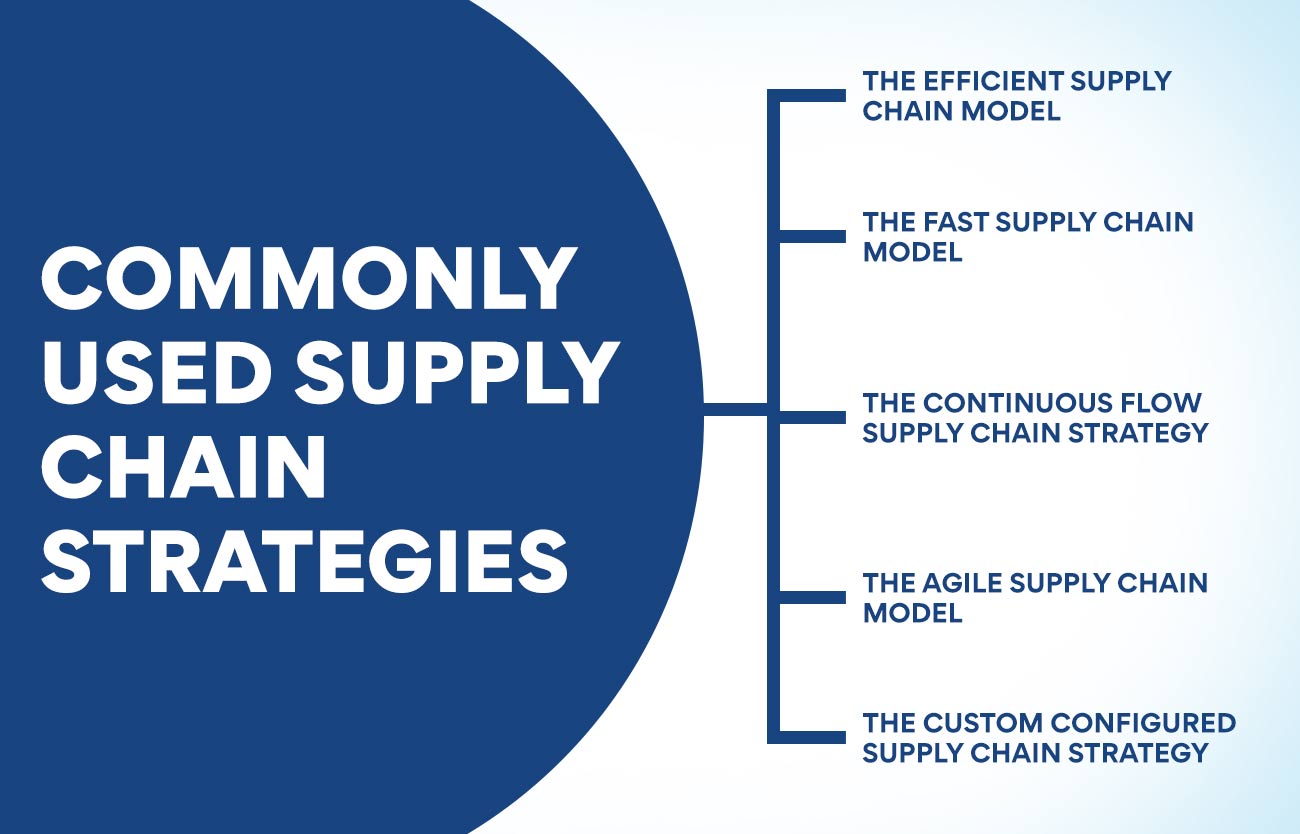

Commonly Used Supply Chain Strategies

- The Efficient Supply Chain Model

It is best for companies that face stiff competition in the market. Most often, the competition is among products that customers don’t perceive to have much difference from one another. The competition is mainly on price. Customers of these products choose their brand based on the best prices offered at any time. It means that the companies must prepare themselves for highs and lows in sales. The firm must schedule its production based on the immediate demand forecast. The best supply chain strategy would be to ensure the best price and perfect order fulfilment.

SC managers should focus on achieving maximum end-to-end efficiency. They must strive to achieve maximum asset usage and high overall equipment efficiency to ensure reduced product cost. In addition, they must ensure high accuracy in demand forecast so that the product is available to meet the fluctuating customer demand. To make this supply chain strategy successful, companies must see that there is always extra capacity in outbound logistics so that supply in times of high demand is not affected. The company must also have extra storage space to store more items when demand is high.

- The Fast Supply Chain Model

This supply chain strategy is most suited for organisations that produce trendy items with a short life cycle. Customers are likely to prefer products that are updated to have features according to the latest trends. It forces manufacturers to produce new items regularly to meet the changing trends in the market. These should also be available at an affordable price to the customer. Organisations in this category must also strive to reduce market mediation costs as much as possible. They can do this by understanding market trends and consumer habits.

Companies with this supply chain strategy must have a pool of suppliers that can provide the additional capacity needed when there is high demand. These firms must use state-of-the-art forecasting techniques to ensure the highest accuracy. They must also employ a synchronised sales and operations planning process. As the product portfolios are extensive and keep changing frequently, it is possible that there are SKUs with low sales volumes. Hence the firm must be able to produce small lots efficiently and procure raw materials in small quantities.

Also Read: What is supply chain analytics? Importance, usage & examples

- The Continuous Flow Supply Chain Strategy

This supply chain strategy is suitable when the demand and supply are steady, and the process ensures a continuous flow of information and products. It is suitable for industries that are mature, and there is hardly any variation in the customer demand profile. In this model, the production is scheduled in such a way that it continuously replenishes stock to attain predefined stock levels. To face competition, these companies must position themselves as regular suppliers of items that reduce the inventory levels at the customer facilities. These firms also assure high levels of service quality.

These companies must have a pre-scheduled order cycle where they receive orders from a set of customers on the same day every week. The production cycles should be planned so that there is very little set-up time between two SKUs. Production managers should maintain the production sequence for a long time to gain experience setting up the manufacturing lines. It will greatly reduce the time taken for setting up and consequently reduce the length of the production cycle. This supply chain strategy requires the company to collaborate with high-volume and high-demand variability customers

- The Agile Supply Chain Model

This model is especially suitable for companies manufacturing goods with unique specifications for each customer. These companies use the “made-to-order” method of producing goods. This requires the organisations to be ready to make goods in quantities that exceed the customers’ agreed volumes or with a shorter lead time than agreed upon. This supply chain strategy demands that companies have excess capacity. It allows the firms to have the agility that is required in this model. The products and processes must allow the manufacturing of small batches.

In order to reduce the lead time in these companies, they should stick to products that use the same components and materials. The firm must favour low-variance customers by giving them better prices and charging the high-variance customers a higher price. The organisation must keep a good relationship with key customers to know the changes required in specifications well in advance. This will help predict short-term requirements and make better long-term investment decisions. Companies operating with this supply chain strategy must make sure they maintain a good level of extra capacity to remain agile.

- The Custom Configured Supply Chain Strategy

The main characteristic of this supply chain strategy is the production of goods with multiple configurations on a unique platform. In this model, the relevance between the cost of assets and the total cost is very high. Companies achieve competitiveness in the market by offering unique configurations as per the requirement of the customer. But unlike the agile model, here, the variations are not unlimited. The configurations can vary only within a limited number of combinations of the product specification. These products are made by assembling a set of parts in different ways.

The product variations are achieved by making changes in the way a part or component is mounted. This is done in the assembly line. The company also archives configuration changes by making changes in mixing, packaging and printing. In all cases, the variations come much later in the manufacturing process. As the variations are many, it is very difficult to forecast demand in this supply chain strategy. The companies following this model must make sure that they have extra capacity in the section that comes after configuration to ensure shorter order cycles.

Many organisations want to have all or some of these models running simultaneously to be able to satisfy all customer segments. But each of these strategies requires separate sets of skills that are not compatible within the same supply chain. It is always better for companies to maintain parallel supply chains, each focusing on a separate customer segment.

Conclusion

It is evident from the above that a new supply chain strategy benefits the company on all fronts. It also gives staff members a chance to learn new skills and move to more challenging jobs. Whatever the firm’s objectives, a good supply chain is necessary for achieving them and progressing in that direction. The implementation of a new plan gives the firm an opportunity to explore modern supply chain capabilities and adopt them for improved profits.

More Information:

What is Supply Chain Consulting? Meaning and Frameworks

What is Supply Chain Finance? A Detailed Analysis

Supply Chain Modeling: Types, Models and Best Practices

Supply Chain Management And Retail Industry: An Essential Relation